Main Menu

Menu

Floveyor manufactures a range of screw conveyors, screw feeders and auger conveyors, each engineered to the highest quality and design standards. Whether you need simple horizontal material transfers, precise dosing applications requiring high accuracy, or decanting bulk bags for high-volume truck loading, Floveyor’s screw systems deliver long-term reliability and efficiency.

We have a long history designing screw conveyors that are in continual operation across different industries and thousands of process lines around the globe. Our factory in Western Australia builds equipment for diverse settings, ensuring optimal handling and movement of materials with consistency and precision.

Quality craftsmanship

Engineered to suit your specific application

Clean conveying

Designed for stringent cleanliness and hygiene standards

Custom solutions

Seamlessly interface with other equipment

Our product ranges

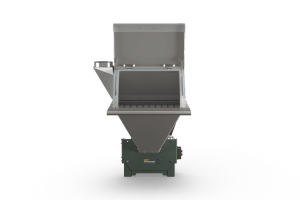

AMC screw feeder

Designed specifically to feed bulk material into a Floveyor aero-mechanical conveyor (AMC) with accurate metering of material, including start/stop operations.

Features

- Variable-speed drive with solid flight screw

- Dust-tight connections

- Safely conveys hazardous materials

- Handles materials that bridge in standard infeed hoppers.

Dosing screw feeder

Designed to accurately dose bulk material into a Floveyor AMC. When paired with a Floveyor reusable or disposable bulk bag unloader, provides accurate loss-in-weight formulation system.

Features

- Variable-speed drive with close clearance solid flight auger

- Start and stop controlled feeding

- Discharges directly into an AMC or TDC

- Safely conveys hazardous material without contamination.

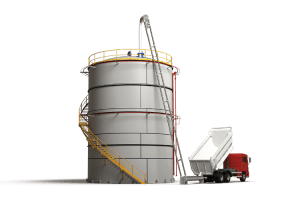

Bulk bag unloader

Unloads disposable or reusable bulk bags. Designed to discharge directly into a Floveyor AMC feed housing.

Features

- Suitable for single or dual hopper arrangements and dump truck/container unloading (via a grain door)

- Variable-speed drive

- Forklift manoeuvrable

- Equipped with safety grids.

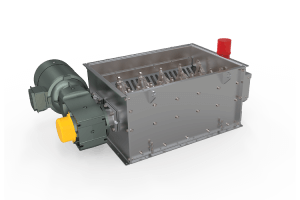

Trough screw feeder

Meters bulk material from multiple sources to a single discharge point, also supports loading from ISO containers, dump trucks, FIBCs, manual bags, and upstream process.

Features

- Hollow shaft inline direct-drive with flexible coupling

- All connections dust-tight under atmospheric pressure

- Standard dimensions to CEMA 300 for component standardisation

- Also discharges via square or circular dropouts.

Build your system

Floveyor provides endless options to build your conveying system for optimal performance and efficiency.

Talk to one of our powder handling specialists about your custom requirements and get a quote for an integrated screw conveyor system for your operation.

Why Floveyor

- Accurate, precise dosing

- Performs in diverse settings

- High cleanability for low contamination risk

- Reliable and efficient

- High availability

- More than 65 years of industry experience

- Powder handling specialists

- Manufactured in Western Australia

Get in touch with Floveyor

Floveyor can work with you to provide tailor-engineered solutions that seamlessly integrate into your existing process lines and interface with other equipment.

Floveyor specialises in the engineering and manufacturing of machines and equipment for the efficient bulk material handling of powders and granules.

©

2024

Floveyor. All rights reserved.