Screw Conveyors

Main Menu

Menu

Home » Conveying » Screw Conveyors » AMC Screw Feeders

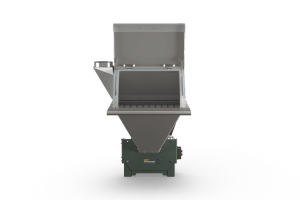

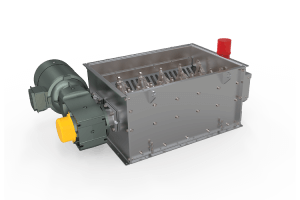

The Floveyor AMC screw feeder has been engineered to provide precise, contamination-free solutions that operate efficiently and are easy to clean. It has a variable-speed drive and for accurate metering of material into the AMC, including start and stop operations. A screw conveyor from Floveyor is well suited to handling materials which tend to bridge in standard infeed hoppers.

Backed by more than 65 years of industry experience, an AMC screw feeder from Floveyor keeps your process running smoothly year after year.

Reliability

Engineered to the highest quality standards

Efficiency

Built to perform in diverse settings

Precision

Optimal handling and movement of materials

Specifications

| Flighting size |

|---|

| 10 inch - 250 mm |

| 12 inch - 300 mm |

| Hopper size | Opening size (width x depth) | Volume |

|---|---|---|

| Small |

600 x 400 mm (23.6 x 15.7 inch) |

120 L 4.2 ft³ |

| Medium |

900 x 900 mm (35.4 x 35.4 inch) |

320 L 11.3 ft³ |

| Large |

1,200 x 900 mm (47.2 x 35.4 inch) |

480 L 16.9 ft³ |

| Nominal speed | 10" (250 mm) | 12" (318 mm) | ||||||

|---|---|---|---|---|---|---|---|---|

| 2:3 Pitch | 1:1 Pitch | 2:3 Pitch | 1:1 Pitch | |||||

| Ribbon | Solid | Ribbon | Solid | Ribbon | Solid | Ribbon | Solid | |

| 20 rpm |

5.0 m3/hr 177 ft3/hr |

7.0 m³/hr 248 ft³/hr |

7.5 m³/hr 266 ft³/hr |

10.5 m³/hr 371 ft³/hr |

7.4 m³/hr 263 ft³/hr |

12.6 m³/hr 445 ft³/hr |

11.2 m³/hr 395 ft³/hr |

18.9 m³/hr 668 ft³/hr |

| 40 rpm |

10.0 m³/hr 355 ft³/hr |

14.0 m³/hr 495 ft³/hr |

15.0 m³/hr 531 ft³/hr |

21.0 m³/hr 741 ft³/hr |

14.9 m³/hr 526 ft³/hr |

25.2 m³/hr 890 ft³/hr |

22.3 m³/hr 789 ft³/hr |

37.8 m³/hr 1,336 ft³/hr |

| 60 rpm |

15.1 m³/hr 532 ft³/hr |

21.0 m³/hr 743 ft³/hr |

22.6 m³/hr 797 ft³/hr |

31.5 m³/hr 1,112 ft³/hr |

22.3 m³/hr 789 ft³/hr |

37.8 m³/hr 1,336 ft³/hr |

33.5 m³/hr 1,184 ft³/hr |

56.7 m³/hr 2,003 ft³/hr |

- 1.1kW [1.5 HP] Geared Motor

- 1.5kW [2.0 HP] Geared Motor

- 2.2kW [3.0 HP] Geared Motor

- 3.0kW [4.0 HP] Geared Motor

- 4.0kW [5.0 HP] Geared Motor

| Voltage | Tolerance | Ph | Hz | Marking |

|---|---|---|---|---|

| 200 V | ± 5% | 3 | 50 | IEC / CE |

| 230 V | ± 5% | 3 | 50 | IEC / CE |

| 400 V | ± 5% | 3 | 50 | IEC / CE |

| 400 V | ± 5% | 3 | 60 | IEC / CE |

| 200 V | ± 5% | 3 | 60 | UL / CSA |

| 230 V | ± 5% | 3 | 60 | UL / CSA |

| 460 V | ± 5% | 3 | 60 | UL / CSA |

| 575 V | ± 5% | 3 | 60 | UL / CSA |

- Carbon Steel (Painted)

- AISI 316(L) Contact Parts, Carbon Steel (Painted) Structural

- AISI 316(L) Contact, 304(L) Structural

Levelling feet

Provided as standard for installation in a fixed location.

Castor wheels

Available when the screw feeder requires frequent relocation.

AMC mobile frame

Allows for both units to be manoeuvred as a single unit.

Open

Provided with grid compliant with AS/NZS and ISO safety standards for machine guarding.

Adaptor lid

Central circular inlet upstand allowing for flexible connection to upstream process.

Bag dump station

Ergonomic height for manual bag unloading.

ATEX 21 Conformity

Suitable for ATEX Zone 21 and 22 Dust Environments.

Build your system

Get tailor-engineered solutions for your production facility that seamlessly integrate into your existing process lines.

Talk to one of our powder handling specialists about your requirements and get a quote for a custom feed screw system.

Why Floveyor

- AS/NZS/ISO/EN design standards

- Integrated surge hopper

- Safely conveys hazardous materials

- Reduces dust

- Horizontal material transfers

- Operates in diverse settings

- Dust-tight connections prevent product contamination

- Manufactured in Western Australia

Get in touch with Floveyor

A Floveyor AMC Screw Feeder increases the value of your operation by ensuring efficient material handling and reduced downtime.

Floveyor specialises in the engineering and manufacturing of machines and equipment for the efficient bulk material handling of powders and granules.

©

2024

Floveyor. All rights reserved.