Products

Main Menu

Menu

Home » Material Conditioning

Floveyor conditioning solutions are designed to enhance the usability and consistency of raw materials, ensuring they meet the high standards required for diverse industrial applications. Engineered to address common issues like lumps, clumps, and metallic contamination, our bulk bag conditioner systems prepare materials efficiently and safely.

From inline lump breakers to advanced sieving mechanisms, Floveyor equipment is tailored to reduce downtime and maintain material consistency. This ensures materials dissolve properly, flow smoothly through processes, and are free of unexpected impurities, supporting a streamlined production environment.

Effective lump and clump reduction

Incorporates rotary lump breakers and sieves to resolve agglomerations and ensure uniform particle size for optimal processing.

Metallic contamination control

Features inline magnets to capture and remove any metallic foreign bodies, enhancing product purity and safety.

Bulk bag

reconditioning

Offers robust FIBC conditioners to restore bulk materials that have compacted during storage or transport.

Our products

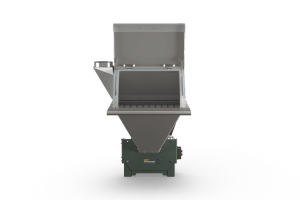

Designed for the simple deagglomeration of compacted materials into smaller particles.

Rotary lump breaker

Simple modular solution for decanting standard bulk bags.

Features

- Conditions lumps up to 200 mm

- Throughputs up to 20m3/hr

- Available in four sizes

Bulk bag conditioner

Designed to break down rock-hard material in bulk bags to the ideal size, guaranteeing smooth discharge to integrated downstream equipment.

Features

- 9,000 kg crushing force

- 3 minute bag conditioning cycle

- Manual or fully automated options

Build your system

Ensure your bulk materials flow freely. Floveyor bulk bag conditioner systems prepare your material for safe, efficient conveying.

Talk to one of our powder handling specialists about the material challenges you experience and get expert advice on how to optimise your process.

Why Floveyor

- Heavy-duty, standards-based design AS/NZS, ISO, EN

- Modular design

- Dust-tight connections

- Safely condition hazardous materials without contamination

- Handles thousands of bulk materials

- Vastly improves flowability

- Seamlessly integrates with Floveyor AMC

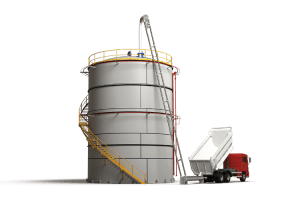

- Supports manual bag, FIBC, and road vehicle unloading

- Power handling specialists since 1958

- Manufactured in Western Australia

Get your materials flowing

Floveyor bulk bag conditioner solutions ensure your material conditioning is operating at peak efficiency.

Floveyor specialises in the engineering and manufacturing of machines and equipment for the efficient bulk material handling of powders and granules.

©

2024

Floveyor. All rights reserved.