Home » Conveying » Screw Conveyors » Dosing Screw Feeders

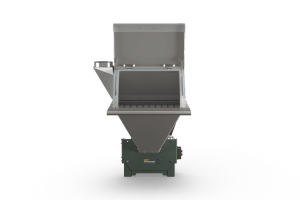

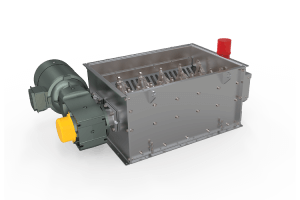

Floveyor’s dosing screw feeder is designed to meter bulk material into a Floveyor aero-mechanical conveyor (AMC) with a high degree of accuracy. The variable-speed drive and close clearance solid flight auger enable precise dosing of powders and granules.

When paired with a Floveyor reusable or disposable bulk bag unloader that is equipped with load cells and a control system, the dosing feeder provides an accurate loss-in-weight formulation system.

Accuracy

Designed to accurately dose bulk material powders and granules into a Floveyor AMC.

Quality design

Highest quality design and manufacturing standards, including AS/NZS/ISO/EN.

Custom solutions

Tailor-engineered to seamlessly integrate with existing plant for optimal efficiency.

Specifications

| Conveyor size | Flighting size |

|---|---|

| F6 | 6 inch / 152 mm |

| F10 | 10 inch / 250 mm |

| F12 | 12 inch / 300 mm |

| Nominal speed | ||||||

|---|---|---|---|---|---|---|

| 6" (150 mm) | 10" (250 mm) | 12" (300 mm) | ||||

| 2:3 Pitch | 1:1 Pitch | 2:3 Pitch | 1:1 Pitch | 2:3 Pitch | 1:1 Pitch | |

| 20 rpm |

1.4 m³/hr 48 ft³/hr |

2.1 m³/hr 72 ft³/hr |

7.0 m³/hr 248 ft³/hr |

10.5 m³/hr 371 ft³/hr |

12.6 m³/hr 445 ft³/hr |

18.9 m³/hr 668 ft³/hr |

| 40 rpm |

2.7 m³/hr 97 ft³/hr |

4.1 m³/hr 145 ft³/hr |

14.0 m³/hr 495 ft³/hr |

21.0 m³/hr 741 ft³/hr |

25.2 m³/hr 890 ft³/hr |

37.8 m³/hr 1,336 ft³/hr |

| 60 rpm |

4.1 m³/hr 145 ft³/hr |

6.2 m³/hr 217 ft³/hr |

21.0 m³/hr 743 ft³/hr |

31.5 m³/hr 1,112 ft³/hr |

37.8 m³/hr 1,336 ft³/hr |

56.7 m³/hr 2,003 ft³/hr |

- 0.37kW [0.5HP] Geared Motor

- 0.55kW [0.75HP] Geared Motor

- 0.75kW [1.0HP] Geared Motor

- 1.1kW [1.5 HP] Geared Motor

- 1.5kW [2.0 HP] Geared Motor

- 2.2kW [3.0 HP] Geared Motor

- 3.0kW [4.0 HP] Geared Motor

- 4.0kW [5.0 HP] Geared Motor

- 5.5kW [7.5 HP] Geared Motor

| Voltage | Tolerance | Ph | Hz | Marking |

|---|---|---|---|---|

| 200 V | ± 5% | 3 | 50 | IEC / CE |

| 230 V | ± 5% | 3 | 50 | IEC / CE |

| 400 V | ± 5% | 3 | 50 | IEC / CE |

| 400 V | ± 5% | 3 | 60 | IEC / CE |

| 200 V | ± 5% | 3 | 60 | UL / CSA |

| 230 V | ± 5% | 3 | 60 | UL / CSA |

| 460 V | ± 5% | 3 | 60 | UL / CSA |

| 575 V | ± 5% | 3 | 60 | UL / CSA |

The dosing screw feeder drive can be mounted at either end of the barrel.

As standard the dosing screw feeder will be supplied with the drive located at the feed end.

- Carbon Steel (Painted)

- AISI 316(L) Contact Parts, Carbon Steel (Painted) Structural

- AISI 316(L) Contact, 304(L) Structural

The standard length is 700 mm [28 in]. Non-standard lengths are available; 600 – 2,000 mm [24 — 79 in] in 100 mm [4 in] increments.

600 mm | 23.62 in |

700 mm | 27.56 in |

800 mm | 31.50 in |

900 mm | 35.43 in |

1,000 mm | 39.37 in |

1,100 mm | 43.31 in |

1,200 mm | 47.24 in |

1,300 mm | 51.18 in |

1,400 mm | 55.12 in |

1,500 mm | 59.06 in |

1,600 mm | 62.99 in |

1,700 mm | 66.93 in |

1,800 mm | 70.87 in |

1,900 mm | 74.80 in |

2,000 mm | 78.74 in |

ATEX 21 Conformity

Suitable for ATEX Zone 21 and 22 Dust Environments.

Wet clean

Drain plug installed in the low point of the dosing screw feeder bed. Recommended for incline augers when liquids may be introduced.

Build your system

A dosing screw feeder from Floveyor, also known as a pencil auger, is part of a complete powder handling system which can be engineered to meet your specific requirements.

Talk to one of our powder handling specialists about your custom requirements for a volumetric feeder system.

Why Floveyor

- Variable-speed drive

- Seamlessly integrates with Floveyor AMC

- Mounts directly to Floveyor RFU/DFU FIBC frame

- Start/stop controlled feeding

- Safely conveys hazardous materials without contamination

- Solid flighting with minimal clearance

- Discharges directly to a Floveyor AMC or TDC via circular dropouts

Get in touch with Floveyor

Floveyor is ready to assist you in developing an accurate loss-in-weight formulation system with tailor-engineered dosing screw feeder systems.

Floveyor specialises in the engineering and manufacturing of machines and equipment for the efficient bulk material handling of powders and granules.

©