Screw Conveyors

Main Menu

Menu

Home » Conveying » Screw Conveyors » Bulk Bag Unloader Screw Feeders

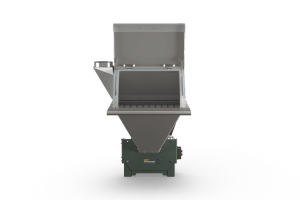

Floveyor’s Bulk Bag Unloader is designed to unload disposable or reusable Flexible Intermediate Bulk Containers (FIBCs). The large, fully enclosed hopper allows for each FIBC to be completely emptied in one go, freeing up the forklift during unloading.

Optional dust extraction is available to minimise environmental contamination and improve workplace air quality.

Quality design

Seamless integration with Floveyor aero-mechanical conveyors.

Versatile

Works with reusable (multi-trip) and disposable (single-trip) FIBCs.

Tailored solutions

Endless design options to accommodate your plant and process line.

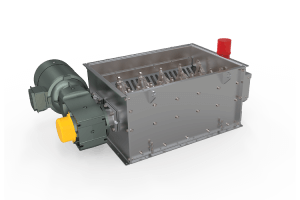

Specifications

Opening size: 1,200 mm W x 1,200 mm D

Volume: Approximately 1,800 L *Model dependant

| Nominal speed | ||||||

|---|---|---|---|---|---|---|

| 10" (250mm) | 12" (300mm) | 14" (366 mm) | ||||

| Ribbon | Solid | Ribbon | Solid | Ribbon | Solid | |

| 20 rpm |

7.5 m³/hr 266 ft³/hr |

10.5 m³/hr 371 ft³/hr |

11.2 m³/hr 395 ft³/hr |

18.9 m³/hr 668 ft³/hr |

17.1 m³/hr 604 ft³/hr |

28.7 m³/hr 1,015 ft³/hr |

| 40 rpm |

15.0 m³/hr 531 ft³/hr |

21.0 m³/hr 741 ft³/hr |

22.3 m³/hr 789 ft³/hr |

37.8 m³/hr 1,336 ft³/hr |

34.2 m³/hr 1,207 ft³/hr |

57.5 m³/hr 2,031 ft³/hr |

| 60 rpm |

22.6 m³/hr 797 ft³/hr |

31.5 m³/hr 1,112 ft³/hr |

33.5 m³/hr 1,184 ft³/hr |

56.7 m³/hr 2,003 ft³/hr |

51.3 m³/hr 1,811 ft³/hr |

86.2 m³/hr 3,046 ft³/hr |

- 1.5kW [2.0 HP] Geared Motor

- 2.2kW [3.0 HP] Geared Motor

- 3.0kW [4.0 HP] Geared Motor

- 4.0kW [5.0 HP] Geared Motor

- 5.5kW [7.5 HP] Geared Motor

- 7.5kW [10.0 HP] Geared Motor

| Voltage | Tolerance | Ph | Hz | Marking |

|---|---|---|---|---|

| 200 V | ± 5% | 3 | 50 | IEC / CE |

| 230 V | ± 5% | 3 | 50 | IEC / CE |

| 400 V | ± 5% | 3 | 50 | IEC / CE |

| 400 V | ± 5% | 3 | 60 | IEC / CE |

| 200 V | ± 5% | 3 | 60 | UL / CSA |

| 230 V | ± 5% | 3 | 60 | UL / CSA |

| 460 V | ± 5% | 3 | 60 | UL / CSA |

| 575 V | ± 5% | 3 | 60 | UL / CSA |

- Carbon Steel (Painted)

- AISI 316(L) Contact Parts, Carbon Steel (Painted) Structural

- AISI 316(L) Contact, 304(L) Structural

Disposable bulk bag

Suited emptying of disposable/single trip bulk bags.

Reusable bulk bag

cutter

The three-blade arrangement allows for cutting of reusable bulk bags.

Reusable bulk bag

Suited for support and untying of reusable/multi-trip bulk bags.

All bulk bag unloader screw feeders (FSFs) are supplied with spigots for connection to dust extraction (blanked off as standard). For dusty products, a bolt-on Manifold, internal to the hopper, is available for optimum extraction. The manifold ensures equal extraction around the peripheral of the hopper, optimising extraction for disposable FIBC unloading.

Lift-in-place weather cover recommended when the bulk bag unloader screw feeder (FSF) will be installed and/or stored outside, to avoid water accumulation from rain or condensation.

Build your system

Every operation is different and Floveyor has more than 65 years of experience helping customers develop their optimal bulk bag unloader system. Start building yours today.

Talk to one of our powder handling specialists about your custom requirements and get a quote for your FIBC unloader screw feeder system.

Why Floveyor

- Suitable for single or dual hopper arrangements

- Variable-speed drive for accurate control of discharge rate

- Equipped with safety grids

- Complete discharge of cohesive bulk materials

- Easy access for maintenance and cleaning

- Suitable for standard ISO shipping containers

- Forklift manoeuvrable

- Manufactured in Western Australia

Optimise your bulk bag unloader system

Floveyor is ready to help you design a bulk bag unloader screw feeder system so you can completely empty each bag and reduce product wastage.

Floveyor specialises in the engineering and manufacturing of machines and equipment for the efficient bulk material handling of powders and granules.

©

2024

Floveyor. All rights reserved.