Home » Food and Beverage Conveying » Tea Conveyor

Meeting the challenges of tea handling

Tea conveying requires a gentle touch, especially if you’re handling all the varieties from green and roasted leaves to instant tea powder. So how do you achieve high throughputs and preserve the quality of your tea?

The aero-mechanical method of conveying (AMC) using FloDisc® Technology is a gentle, rapid and safe way to handle bulk tea Floveyor engineered the fully enclosed design to prevent dust hazards, including build-up in confined spaces which can be combustible. Gentle handling, even at high throughputs, maintains product integrity and ensures the flavour of your tea is preserved. It makes Floveyor the ideal tea conveyor for the safe, bulk material handling of tea.

Material characteristics

Fragile materials

Requires gentle handling, limits system types

Explosive / Hazardous

Stringent safety measures, explosion-proof needs

Odour / colour risks

Potential for cross-contamination, cleaning needs

Our products for tea handling

Conveyor ranges – Tea conveyor

Elementa

Compliance and quality assurance for low-risk, dry food stuffs

- Up to 54 TPH

- Dry clean

- Wet clean

- Certified to American FDA and EU EC regulations

- ATEX 21

Nutria

Clean design benefits for sophisticated food processing

- Up to 30 TPH

- Dry clean

- Wet clean

- Certified to American FDA and EU EC regulations

- ATEX & IECEx Zone 21

Pura

Engineered for stringent global food safety requirements

- Up to 30 TPH

- Certified to American FDA and EU EC regulations

- GMP designs

- Meets EHEDG guidelines

- Dry clean

- Wet clean

- CIP wet clean

- Steam sterilise

- ATEX & IECEx Zone 21

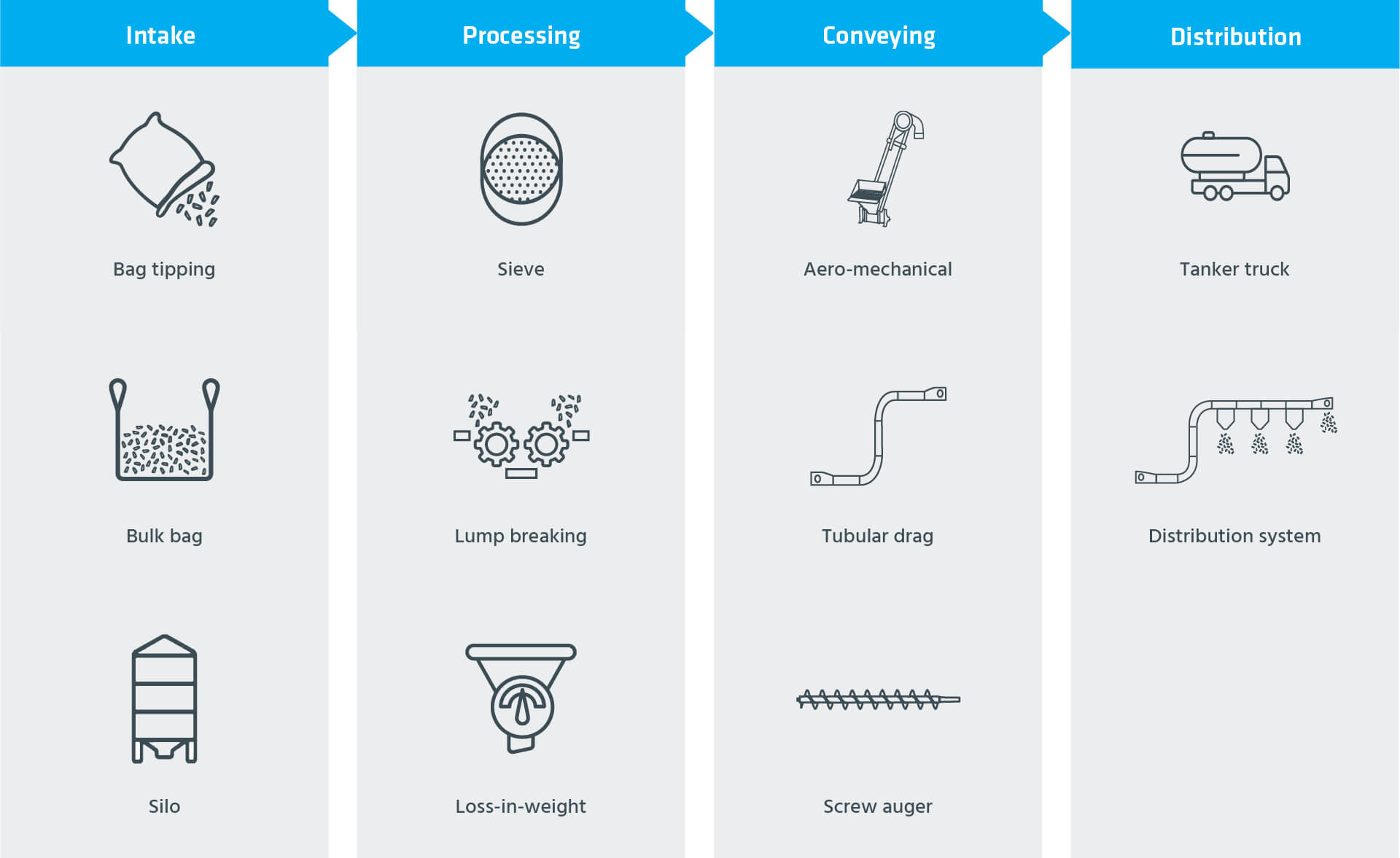

Bulk material handling equipment

Why Floveyor

Floveyor invented the AMC and has been evolving powder handling for 65 years. A single Floveyor can rapidly transfer all varieties of tea with no product degradation and minimal dust. Our tubular drag conveyor (TDC) is ideal for complex routes and multiple discharge points. Floveyor conveyors have a small footprint, are easy to clean, and are available for hazardous applications and in mobile units. They are incredibly energy efficient, making them the green alternative to other food-grade conveying solutions. What’s more, Floveyor has the conveying technology you need to keep your tea process line running safely and efficiently while preserving flavour.

Discover the Floveyor advantage for tea handling, already trusted by a diverse customer base across the globe.

The FloDisc Technology difference

When you take everything into account for optimal food and beverage materials processing, only one conveyor meets all the requirements – Floveyor with FloDisc.® Technology

Perfect your tea process line

Floveyor has optimised bulk material handling for tea processing all over the world. Let’s work together to make sure your plant is delivering your tea products at peak quality, with tea conveyor and process line technology from powder handling specialists.

Send us your product for testing

Check out our R&D test for bulk material handling of multiple materials, including tea leaves. Better yet, get in touch with our powder handling specialists to arrange a test using your own tea product.

Floveyor specialises in the engineering and manufacturing of machines and equipment for the efficient bulk material handling of powders and granules.

©