Screw Conveyors

Main Menu

Menu

Home » Conveying » Screw Conveyors » Trough Screw Feeders

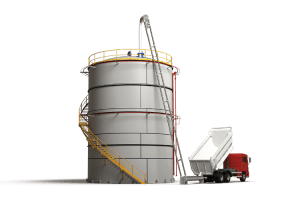

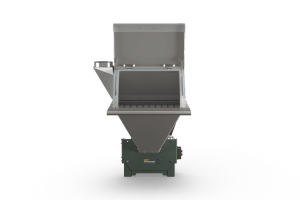

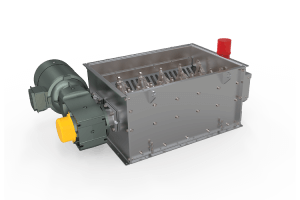

Trough screw feeders from Floveyor are best suited to installations requiring a feeder capable of metering bulk material from a number of sources to a single discharge point. The modular design of the screw feeder accepts a range of accessories, enabling loading of material from intermodal (ISO) containers, dump trucks, FIBCs (bulk bags), manual bags and sacks, as well as direct connection to upstream process.

An optional shroud may be installed on the screw auger to limit material flow to a circular cross-section for accurate dosing applications or when handling highly fluid powders and granules.

Quality design

Designed to the highest engineering and manufacturing standards.

Tailored solutions

Delivers reliability and efficiency, even in complex conveying systems.

Seamless integration

Ensures complete compatibility with Floveyor AMC for optimal powder handling.

Specifications

| Flighting diameter |

|---|

| 10 inch / (250 mm) |

| 12 inch (300 mm) |

| 14 inch (356 mm) |

| Nominal speed | 14” (366mm) | |||

|---|---|---|---|---|

| 2:3 Pitch | 1:1 Pitch | |||

| Ribbon | Solid | Ribbon | Solid | |

| 20 rpm |

11.4 m³/hr 402 ft³/hr |

19.2 m³/hr 677 ft³/hr |

17.1 m³/hr 604 ft³/hr |

28.7 m³/hr 1,015 ft³/hr |

| 40 rpm |

22.8 m³/hr 805 ft³/hr |

38.3 m³/hr 1,354 ft³/hr |

34.2 m³/hr 1,207 ft³/hr |

57.5 m³/hr 2,031 ft³/hr |

| 60 rpm |

34.2 m³/hr 1,207 ft³/hr |

57.5 m³/hr 2,031 ft³/hr |

51.3 m³/hr 1,811 ft³/hr |

86.2 m³/hr 3,046 ft³/hr |

- 0.75kW [1.0HP] Geared Motor

- 1.1kW [1.5 HP] Geared Motor

- 1.5kW [2.0 HP] Geared Motor

- 2.2kW [3.0 HP] Geared Motor

- 3.0kW [4.0 HP] Geared Motor

- 4.0kW [5.0 HP] Geared Motor

- 5.5kW [7.5 HP] Geared Motor

- 7.5kW [10.0 HP] Geared Motor

- 11.0kW [15.5 HP] Geared Motor

| Voltage | Tolerance | Ph | Hz | Marking |

|---|---|---|---|---|

| 200 V | ± 5% | 3 | 50 | IEC / CE |

| 230 V | ± 5% | 3 | 50 | IEC / CE |

| 400 V | ± 5% | 3 | 50 | IEC / CE |

| 400 V | ± 5% | 3 | 60 | IEC / CE |

| 200 V | ± 5% | 3 | 60 | UL / CSA |

| 230 V | ± 5% | 3 | 60 | UL / CSA |

| 460 V | ± 5% | 3 | 60 | UL / CSA |

| 575 V | ± 5% | 3 | 60 | UL / CSA |

- Carbon Steel (Painted)

- AISI 316(L) Contact Parts, Carbon Steel (Painted) Structural

- AISI 316(L) Contact, 304(L) Structural

Length of the feeder, measured in number of 250mm (9.8 in) long panels. Available from 2—20 panels inclusive.

| Panels | ||

|---|---|---|

| Length | ||

| 02 | 500 mm | 19.69 in |

| 03 | 750 mm | 29.53 in |

| 04 | 1,000 mm | 39.37 in |

| 05 | 1,250 mm | 49.21 in |

| 06 | 1,500 mm | 59.06 in |

| 07 | 1,750 mm | 68.90 in |

| 08 | 2,000 mm | 78.74 in |

| 09 | 2,250 mm | 88.58 in |

| 10 | 2,500 mm | 98.43 in |

| 11 | 2,750 mm | 108.27 in |

| 12 | 3,000 mm | 118.11 in |

| 13 | 3,250 mm | 127.95 in |

| 14 | 3,500 mm | 137.80 in |

| 15 | 3,750 mm | 147.64 in |

| 16 | 4,000 mm | 157.48 in |

| 17 | 4,250 mm | 167.32 in |

| 18 | 4,500 mm | 177.17 in |

| 19 | 4,750 mm | 187.01 in |

| 20 | 5,000 mm | 196.85 in |

Rectangular flanged

Outlet available as a rectangular flange.

Circular dropout

Outlet available as a circular transition.

Aero-mechanical discharge

Discharges directly to an AMC without the need for an inlet hopper.

Levelling feet

Provided as standard for installation in a fixed location.

Castor wheels

Available when the screw feeder requires frequent relocation.

Fixed frames

Fixed Frame mounting feet are recommended for heavy duty applications or where the TSF will be installed in an elevated location.

Open

For direct connection to upstream equipment.

Adaptor lid

Central circular inlet upstand allowing for flexible connection to upstream process.

Bag dump station

Ergonomic height for manual bag unloading.

The trough screw feeder drive can be mounted at either end of the trough.

ATEX 21 Conformity

Suitable for ATEX Zone 21 and 22 Dust Environments.

Wet clean

Drain Plug installed in the low point of the trough screw feeder bed. Recommended for incline augers when liquids may be introduced.

Build your system

Floveyor trough screw feeder systems perform in diverse settings, ensuring your bulk material handling operates with consistency and precision.

Talk to one of our powder handling specialists about your custom requirements for a trough screw feeder for your process line.

Why Floveyor

- Dust tight under atmospheric pressure

- Discharges directly to an AMC

- Component standardisation

- Accepts a wide range of accessories

- Quick access to maintenance areas

- Manufactured in Western Australia

- More than 65 years of industry experience

- Powder handling specialists

Optimise your plant with a Floveyor trough screw feeder

Floveyor auger conveyors are in daily operation all over the world in a diverse range of industries. We’re ready to help you optimise your process line for maximum efficiency.

Floveyor specialises in the engineering and manufacturing of machines and equipment for the efficient bulk material handling of powders and granules.

©

2024

Floveyor. All rights reserved.