Products

Main Menu

Menu

Home » Batching and Weighing

Floveyor batch weighing systems are engineered to meet the demands of medium-sized manufacturers aiming to automate and refine their production processes. Designed to integrate seamlessly into existing facilities, these systems offer precision in handling diverse ingredients, ensuring high-quality outputs with minimal waste.

Ideal for industries such as food, chemicals, and construction, our weigh filling machine systems facilitate accurate dosing and blending of multiple ingredients, improving consistency and efficiency. Their compact and flexible design allows easy fitment into various plant layouts, optimising space and enhancing production flow without the extensive cost of complete automation.

Versatile ingredient handling

Automatically adjusts to handle a wide range of raw materials, ensuring efficient processing without manual reconfiguration.

Integrated system design

Seamlessly fits into existing production lines, enhancing efficiency without significant modifications or disruptions.

High precision weighing

Delivers precise dosing with high accuracy for each ingredient, crucial for quality control and consistency.

Our products

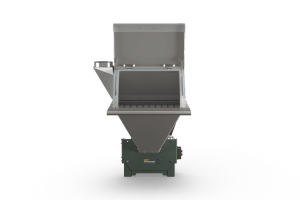

Loss-in-weight

Designed to provide an accurate, multi-material batching system.

Features

- Suitable for reuseable or disposable bulk bag discharging frames

- Supplied with load cells only or with control interface

- Modular systems designed to interface with our dosing augers and rotary lump breakers

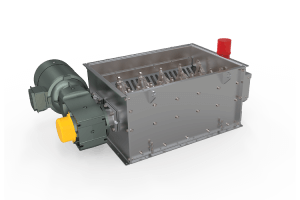

Formulation system

Delivers total batch transfers due to combined mechanical/pneumatic conveying action.

Features

- Accurate loss-in-weight batch controller with optional HMI controller

- Batch major materials from bulk bags

- Minors from manual bag dump stations

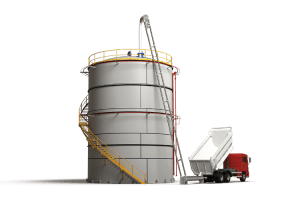

Build your system

Build your weigh batching system to ensure maximum efficiency and accuracy with minimal residue and no cross-contamination. Floveyor offers tailored solutions that effortlessly handle bag unloading, storage, and conveying.

Talk to one of our powder handling specialists about how to introduce automation into your batch weighing system.

Why Floveyor

- Modular solution

- Energy-efficient

- Seamlessly integrates with Floveyor machinery and equipment

- High throughputs

- Total batch transfers

- Accurate, multi-material batching systems

- Highly cleanable

- Designed for low-headroom installations, perfect for brownfield sites

- Low total cost of ownership

- Manufactured in Western Australia

Optimise your batch weighing system

Discover how you can add automation or improve your current Formulation System without incurring significant costs or the complexity of a full-scale automated line.

Floveyor specialises in the engineering and manufacturing of machines and equipment for the efficient bulk material handling of powders and granules.

©

2024

Floveyor. All rights reserved.