Bag Unloading

Main Menu

Menu

Home » Bag Unloading » Reusable Bulk Bag Dischargers

Floveyor reusable bulk bag dischargers are engineered to offer sustainability and operational efficiency. They are ideal for handling thousands of bulk materials in various industrial applications. These dischargers minimise waste and maximise cost-efficiency, contributing to long-term lower cost of ownership.

Equipped with a structurally certified frame and ergonomic design, Reusable Bulk Bag Unloaders ensure safety and comfort for operators while handling materials. The versatile configurations, including forklift and hoist loading options, accommodate different plant layouts and process requirements, providing a seamless integration into existing systems. A Floveyor AMC paired with our reusable flexible intermediate bulk containers (FIBC) dischargers is the ideal solution for fast, safe powder handling solutions.

Advanced dust-suppression

technology

Features cutting-edge systems that contain dust emissions, ensuring a clean and compliant work environment.

Modular and customisable solutions

Easily adaptable to meet specific industrial needs, ensuring compatibility with various bag sizes and system layouts.

High-efficiency unloading systems

Designed for quick and efficient material discharge, reducing downtime and enhancing overall productivity.

Our products

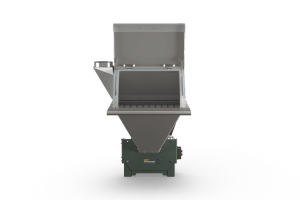

Forklift reusable bulk bag discharger

Simple modular solution for decanting standard bulk bags.

Features

Fixed frame with adjustable-height bulk bag carrier

Ergonomic height to access door

1.5 t (1.65 ton) rated capacity

Low-profile forklift reusable bulk bag discharger

Ideal in areas with restricted headroom or where the forklift has a short mast.

Features

Top half of the frame can be removed and loaded with an bulk bag at ground level

1.5 t (1.65 ton) rated capacity

Hoist reusable bulk bag discharger

Designed to be loaded without a forklift, the hoist system features a monorail and an electric chain hoist.

Features

› Structurally certified monorail and bulk bag carrier

Typically loaded with palletised bulk bags, moved using a pallet jack

1.5 t (1.65 ton) rated capacity

Specifications

Floveyor integrated reusable bulk bag dischargers and unloaders provide one of the most effective and reliable solutions for getting your bulk materials into the plant.

Plain

The plain tundish is designed to support the bulk bag and create a dust tight seal during unloading.

Bridge breaking

bag paddles

Mechanical bridge breaking massagers aid in the discharge of even the most difficult of flow properties.

Single station

Ideal for most low volume applications requiring only a single point of discharge.

Dual station

Provides more than double the unloading capacity of a single station discharger. Provides optimised capital cost and reduces operating costs.

Enclosed

Untying chamber with quick-access dust-tight access door. Spigot provided for connection to site dust extraction.

Clamped

Bag spout clamping that provides a dust tight seal that won’t leak or release during discharge.

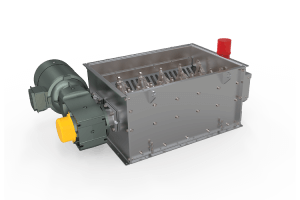

Lump breaker

Designed to reduce lumps to comply with the particle size limits of downstream equipment.

Shut-off valve

A pneumatically actuated, pinch-type valve used to control or shut off the flow from a loaded bulk bag. Suits spout diameters up to 350mm.

Load cells

Bulk bag dischargers can be supplemented with analogue output load cells to provide functionality for accurate dosing and/or batching.

- Carbon Steel (Painted)

- AISI 316(L) Contact Parts, Carbon Steel (Painted) Structural

- AISI 316(L) Contact, 304(L) Structural

Get in touch with one of our powder handling specialists about how to get the most value out of your spout bulk bag unloader solution.

Build your system

Advantages

- Easy maintenance and sanitation

- Precision in dispensing materials

- Broad range of bag sizes and specs

- Safe and reliable unloading

- Works with reusable and string-tied bottom spout FIBCs

- Integrates easily with Floveyor AMC

- Fits with existing process lines

- Single FIBC or double FIBC frame configurations

- Lower total cost of ownership

- 60+ years of development

Minimise downtime with Floveyor reusable bulk bag dischargers

Find out how you can keep your powder handling production flowing safely and efficiently.

Floveyor specialises in the engineering and manufacturing of machines and equipment for the efficient bulk material handling of powders and granules.

©

2024

Floveyor. All rights reserved.