Bag Unloading

Main Menu

Menu

Home » Bag Unloading » Disposable Bulk Bag Discharger

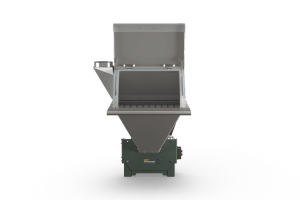

Floveyor disposable bulk bag dischargers are meticulously designed for one-time use bulk bag applications, ensuring efficient handling and complete discharge of materials. Manufactured to accommodate various flat-bottom bag designs, these unloaders are pivotal in reducing operational waste and enhancing productivity within tightly regulated environments.

Featuring a structurally certified and ergonomically optimised frame, our unloaders provide a safe and convenient operation. The integrated cutting blades and dust control systems ensure each unloading process is clean and compliant, maintaining the integrity of both the product and the workplace.

High-speed throughput

Engineered for efficiency, significantly reducing unloading times and increasing overall production flow.

Universal bag compatibility

Adaptable to different bag specifications and sizes, accommodating industry variability without sacrificing performance.

Advanced dust control features

Incorporates specialised systems to minimise dust emissions, enhancing workplace safety and meeting stringent health standards.

Our products

Bulk bag held-in-place

The integrated bag carrier allows the bulk bag to be safely left in place during unloading, acting as a partial hopper while gradually discharging raw material.

Features

Designed to decant disposable (single-trip) flat bottom bulk bags

Incorporates a bulk bag carrier, a fixed frame and a transition hopper

Suitable for forklift loading

Adjustable bulk bag carrier to suit variable bag heights

Suits bulk bags without internal liners

Half frame

The half frame variant is suitable when the bulk bag will be supported by forklift or overhead hoist.

Features

Designed to decant disposable (single-trip) flat bottom bulk bags

Suits bulk bags without internal liners

Specifications

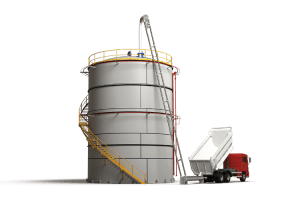

A Floveyor AMC paired with our disposable bulk bag dischargers is one of the most effective and reliable solutions for getting your bulk materials into your plant, a storage vessel, or a road vehicle. Learn more about building an ideal powder handling system.

Disposable bulk bag

Suited for piercing and emptying of disposable / single-trip bulk bags. A central spike pierces the bag, while 4 x tool hardened and sharpened blades slice open the bag from corner to corner. Leaving minimal residue within the bag.

Reusable bulk bag

cutter

A variant of the disposable bulk bag cutting arrangement, modified to cut reusable / multi-trip bags. The three-bladed cutting arrangement cuts around the reusable bulk bag spout, creating a “flap” which drops away from the underside of the bag.

Single station

Ideal for most low volume applications requiring only a single point of discharge.

Dual station

Provides more than double the unloading capacity of a single station discharger. Provides optimised capital cost and reduces operating costs as both dischargers can feed into a single AMC or trough screw feeder. Also suitable for forklift loading.

- Carbon Steel (Painted)

- AISI 316(L) Contact Parts, Carbon Steel (Painted) Structural

- AISI 316(L) Contact, 304(L) Structural

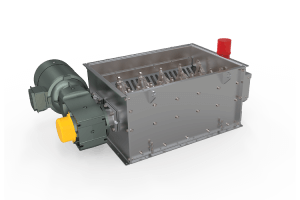

Lump breaker

Designed to reduce lumps to comply with the particle size limits of downstream equipment.

Shut-off valve

A pneumatically actuated, pinch-type valve used to control or shut off the flow from a loaded bulk bag. Suits spout diameters up to 350mm.

Load cells

Bulk bag dischargers can be supplemented with analogue output load cells to provide functionality for accurate dosing and/or batching.

Get in touch with one of our powder handling specialists about how to get the most value out of your single trip bulk bag unloader solution.

Build your system

A Floveyor AMC paired with our disposable bulk bag dischargers is one of the most effective and reliable solutions for getting your bulk materials into your plant, a storage vessel, or a road vehicle. Learn more about building an ideal powder handling system.

Advantages

- Integrated bag carrier allows FIBC to be safely left in place

- Acts as a partial hopper while gradually discharging material

- Minimises contamination from strings and torn plastic

- Completely opens FIBCs on first attempt

- Contains dust and spillage

- Safe and convenient for operators

- Granularly discharges material via high/low lever sensors or at consistent feed rate

- Suitable for applications such as liquid mixing tanks

- Manufactured in Western Australia

60+ years of development

Get safe, controlled flat-bottom bulk bag dischargers

Floveyor single trip bulk bag unloaders let you discharge raw materials safely and efficiently with minimal product wastage. Find out more.

Floveyor specialises in the engineering and manufacturing of machines and equipment for the efficient bulk material handling of powders and granules.

©

2024

Floveyor. All rights reserved.