Bag Unloading

Main Menu

Menu

Home » Bag Unloading » Bag Dump Station

Engineered to meet the stringent demands of industries where manual handling of powdery and granular materials is prevalent, Floveyor bag dump stations offer a solution that marries safety with efficiency. Designed and manufactured to facilitate easy operation and maintenance, these stations help reduce physical strain and minimise dust emissions, crucial in maintaining a clean and safe work environment.

Our stations ensure a rapid processing speed and seamless integration into existing production lines, preventing bottlenecks and promoting productivity while adhering to high hygiene standards and reducing cross-contamination risks.

Advanced dust suppression

Incorporates cutting-edge dust control to ensure a safe, clean workplace by effectively containing airborne particles.

Hygienic and easy to clean

Quickly processes various bag sizes and weights, maintaining consistent workflow and preventing production delays.

High throughput

efficiency

Quickly processes various bag sizes and weights, maintaining consistent workflow and preventing production delays.

Specifications

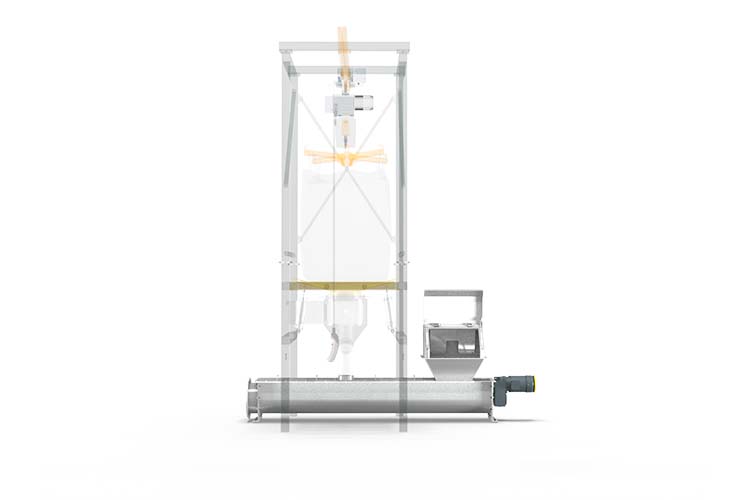

A Floveyor AMC paired with our bag dumping station is one of the most effective and reliable solutions for your bulk material handling applications. Build your ideal system.

Splash guard

Ideal for manual bag unloading of granular and non-dusty materials. Designed to minimise spillage around the tipping point, ensuring a cleaner work area.

Dust hood

Connects to plant dust extraction systems to minimise environmental and plant contamination during debagging, ensuring a cleaner and safer work environment.

Dust hood with process inlet

A manual bag unloading station that can also receive material from an upstream process or a Floveyor bulk bag discharger, providing versatile integration options.

Dust hood with integrated dust collector

When plant extraction is not available, an integrated dust collector can be added directly to the bag dump station, ensuring efficient dust control and maintaining a clean environment.

Aero-mechanical conveyor

Features a transition hopper and interface to the Floveyor aero-mechanical conveyor for direct transfer to downstream processes, ensuring efficient material handling.

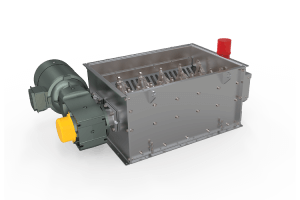

Tubular drag conveyor

Equipped with a transition hopper and interface to the Floveyor tubular drag conveyor, facilitating direct transfer to downstream processes.

Screw feeder hopper

Combines all the advantages of the bag dump station and dust hood with the added benefits of controlled feed from a surge hopper. The increased hopper storage volume allows for pre-loading batches, while the feeder’s variable speed drive and level sensors ensure precise metering to downstream processes.

Trough screw feeder

Incorporates a transition hopper and interface to the Floveyor trough screw feeder, enabling multiple infeed options and direct transfer to downstream processes.

Custom

Custom interfaces are available to integrate Floveyor bag dump stations with existing plant and equipment, tailored to specific requirements.

Vibrating grid

The small aperture mesh grid with applied vibration ensures consistent powder delivery without interruption.

Hopper vibrator

A rotary vibrator mounted to the infeed ensures material flow and reduces the risk of bridging and poor flow.

Bin aerator

Bin aerators can be used with a closed door to prompt the flow of even the most difficult materials.

Quick release access

Quick release access with integrated safety interlocks facilitates effortless disassembly for cleaning and validation.

Get in touch with one of our powder handling specialists about how to get the most value out of your bulk bag dump station.

Build your system

Advantages

- Reduces dust emitted during dumping process

- Minimises material loss and environmental contamination

- Ergonomic working height minimises risk of operator discomfort

- Easy tip operation

- Maximises throughput potential

- Suitable for granular materials

- Easy to clean

- Suitable for food-grade materials

- 60+ years of development

- Manufactured in Western Australia

Prevent production bottlenecks with a Floveyor bag dump station

Find out how Floveyor bag dump stations safely and efficiently empty bulk bags and integrate with the rest of your production line.

Floveyor specialises in the engineering and manufacturing of machines and equipment for the efficient bulk material handling of powders and granules.

©

2024

Floveyor. All rights reserved.